Yes that is a printer. You can always tell the geeks apart from men as the spot the Tech stuff! Disappointed you didn't guess the model though!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welcome to our Community

Wanting to join the rest of our members? Feel free to sign up today.

Sign up

is this your printer on the right site??

Is that fermenting to how you brew that lol

There is no bounds to this mans resourcefulness

Yes that is a printer. You can always tell the geeks apart from men as the spot the Tech stuff! Disappointed you didn't guess the model though!

its a Epson Laser Color Printer

Fermentation looked as though it has completed, no bubble activity for a day!

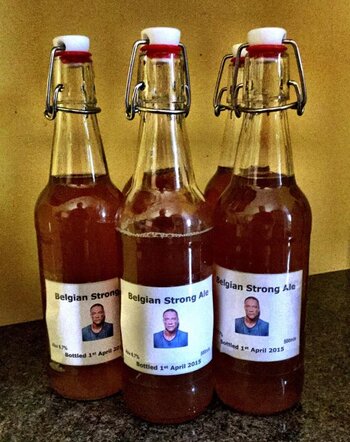

So bottling time it was. This beer is an experiment in a few ways. First this was my own recipe based on a few others to get a feel for the malt ratios to use. Tasting it as I siphoned it I feel it isn't too far away from what I was hoping to achieve. Taking a few sips at this stage is only a guide as it still has some conditioning to go through. The second experiment is to use some clearing agent to try and clear the beer. Without filtering or using Irish moss or some other similar substance to clear the beer it is quite probably going to be slightly cloudy. As you chill beer proteins come out of solution and make it cloudy. These additions combine with those proteins and create a sludge at the bottom. For this batc I used an agent that you add to the beer after syphoning out of the fermentation vessel, give it a shake and let it settle. Initially at bottling it does look clearer and bottle conditioning should clear it further. So I have now put it away for a few weeks.

Yeild from this batch is 4.75 500ml bottles. Less than I have got with some batches because there was quite a deep sediment on the bottom of the fermentor and some further loss with the clarity stuff.

I've also used clear bottles for this batch. There are risks involved as light can affect beer but where I'm storing it is cool and dark so that shouldn't be a problem. With bottle conditioned beer you still get some sediment at the bottom and a clear bottle should make it easier to pour.

Also my second brew (Grapefruit and Honey Ale) is ready to sample. tastes like beer! Which is a good start but not overly stunning. Definitely a sessionable beer. Not really enough hop action for me. Last of the two kits that I have done.

So bottling time it was. This beer is an experiment in a few ways. First this was my own recipe based on a few others to get a feel for the malt ratios to use. Tasting it as I siphoned it I feel it isn't too far away from what I was hoping to achieve. Taking a few sips at this stage is only a guide as it still has some conditioning to go through. The second experiment is to use some clearing agent to try and clear the beer. Without filtering or using Irish moss or some other similar substance to clear the beer it is quite probably going to be slightly cloudy. As you chill beer proteins come out of solution and make it cloudy. These additions combine with those proteins and create a sludge at the bottom. For this batc I used an agent that you add to the beer after syphoning out of the fermentation vessel, give it a shake and let it settle. Initially at bottling it does look clearer and bottle conditioning should clear it further. So I have now put it away for a few weeks.

Yeild from this batch is 4.75 500ml bottles. Less than I have got with some batches because there was quite a deep sediment on the bottom of the fermentor and some further loss with the clarity stuff.

I've also used clear bottles for this batch. There are risks involved as light can affect beer but where I'm storing it is cool and dark so that shouldn't be a problem. With bottle conditioned beer you still get some sediment at the bottom and a clear bottle should make it easier to pour.

Also my second brew (Grapefruit and Honey Ale) is ready to sample. tastes like beer! Which is a good start but not overly stunning. Definitely a sessionable beer. Not really enough hop action for me. Last of the two kits that I have done.

Attachments

Last edited:

Tried my partial wheat ale and the 60-minute IPA.

The partial wheat ale tasted OK for a first attempt at my own recipe but was a little lacking in body and was quite light. Was also a bit flat - not sure why that is so need to swat up on the possible reasons for that. Added sugar to the bottle but may be not enough.

The 60-minute IPA was the half bottle but I was interested in seeing what that was like as I was going to have another go at this one next week. Hoppy! Very bitter but has a lot of floral citrus aroma. This does need another 5 weeks before it should be ready but looks like it should be good. A little light in colour so the malts in the recipe may need to be changed.

The partial wheat ale tasted OK for a first attempt at my own recipe but was a little lacking in body and was quite light. Was also a bit flat - not sure why that is so need to swat up on the possible reasons for that. Added sugar to the bottle but may be not enough.

The 60-minute IPA was the half bottle but I was interested in seeing what that was like as I was going to have another go at this one next week. Hoppy! Very bitter but has a lot of floral citrus aroma. This does need another 5 weeks before it should be ready but looks like it should be good. A little light in colour so the malts in the recipe may need to be changed.

thinking at glen after i mowed the lawn yesterday.

drinking a nice cold beer. i tried some special ( organic ) "Keller Bier" beer and it was very tastfull.

Entdecke die Welt der Störtebeker Brauspezialitäten

drinking a nice cold beer. i tried some special ( organic ) "Keller Bier" beer and it was very tastfull.

Entdecke die Welt der Störtebeker Brauspezialitäten

Found a beer shop in Edinburgh that imports a lot of European beers so I have made a note and will see if they have any of that.

Planning on doing another brew next week and trying the IPA again. I have sampled some of the recent batches and the ones from my recipes. All have been under carbonated. You add sugar to the bottle and the residual yeast in the beer starts fermenting and carbonates the beer but mine was nearly flat. After some checking, I found it is best if you leave the beer at room temperature initially so the yeast can get to work. As I was putting the bottles out and into the cellar (also known as the garage) the temperature was and has been about 4°C most of the time. At that temp the yeast becomes dormant so no carbonation. I have brought the beer into the house to warm it up and hopefully that will encourage the yeast to start fermenting the remaining sugar in the bottle.

The last two batches where I used a clarifying agent look nice and clear and despite the lack of CO2 taste rather good.

Planning on doing another brew next week and trying the IPA again. I have sampled some of the recent batches and the ones from my recipes. All have been under carbonated. You add sugar to the bottle and the residual yeast in the beer starts fermenting and carbonates the beer but mine was nearly flat. After some checking, I found it is best if you leave the beer at room temperature initially so the yeast can get to work. As I was putting the bottles out and into the cellar (also known as the garage) the temperature was and has been about 4°C most of the time. At that temp the yeast becomes dormant so no carbonation. I have brought the beer into the house to warm it up and hopefully that will encourage the yeast to start fermenting the remaining sugar in the bottle.

The last two batches where I used a clarifying agent look nice and clear and despite the lack of CO2 taste rather good.

Beer taste/freshness.

The main enemy of beer is air or rather oxygen. O2 surprisingly helps cause oxidation which isn't a good thing. UV light will also affect the beer which is why nearly all beer bottles are brown. Glass is also a pretty neutral substance so doesn't add to the flavour. A while back tins would taste different to bottled drinks as they would add a slight metallic taste as the lacquer wasn't good enough. Like most things technologies change and improve which is probably why tins are becoming used more for even craft beers.

Glass and aluminium are both very recyclable but weight is less per container/volume for a tinned beer so that means less transportation costs. Initially aluminium costs a lot to produce but recycling costs are very low. Glass is easy to recycle though you do need a lot of energy. Plastic bottles aren't used as a carbonated beverage will gradually become flat. Plastic PET bottles are gas permeable and even Coke in plastic doesn't have a very long shelf life. When I worked the a brewery laboratory we tested varies alternatives to tins and bottles and none were very good at all.

A recent introduction is nitro beers which utilise CO2 and nitrogen as the gassing agent. Though neutral, nitrogen can affect mouth feel and taste of a beer compared to just CO2. Tends to be stouts and porters that are using nitrogen.

Another change is that other hop varieties are being used and the Moor beer Hoppiness uses Citra which gives a much fresher and fragrant taste.

The main enemy of beer is air or rather oxygen. O2 surprisingly helps cause oxidation which isn't a good thing. UV light will also affect the beer which is why nearly all beer bottles are brown. Glass is also a pretty neutral substance so doesn't add to the flavour. A while back tins would taste different to bottled drinks as they would add a slight metallic taste as the lacquer wasn't good enough. Like most things technologies change and improve which is probably why tins are becoming used more for even craft beers.

Glass and aluminium are both very recyclable but weight is less per container/volume for a tinned beer so that means less transportation costs. Initially aluminium costs a lot to produce but recycling costs are very low. Glass is easy to recycle though you do need a lot of energy. Plastic bottles aren't used as a carbonated beverage will gradually become flat. Plastic PET bottles are gas permeable and even Coke in plastic doesn't have a very long shelf life. When I worked the a brewery laboratory we tested varies alternatives to tins and bottles and none were very good at all.

A recent introduction is nitro beers which utilise CO2 and nitrogen as the gassing agent. Though neutral, nitrogen can affect mouth feel and taste of a beer compared to just CO2. Tends to be stouts and porters that are using nitrogen.

Another change is that other hop varieties are being used and the Moor beer Hoppiness uses Citra which gives a much fresher and fragrant taste.

i think the main enemy of beer is the guy who opened the bottle.

Not a great fan of whisky. Only really enjoyed Rosbank which is very hard (and expensive to get now). Got Isobel a magnum of it a while ago for £50. Seen them going for about £1,000 now! Luckily I got two then. Waiting for it to be worth a new car before selling it! Rather sell it than drink it.

There are some amazing small batch gins though.

Yes that shop is great.

There are some amazing small batch gins though.

Yes that shop is great.

Been starting again since about 2012. There was also another one that they started building near here but that stopped too.

Well it seems rosebank will be back thoughBeen starting again since about 2012. There was also another one that they started building near here but that stopped too.

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)